This article to introduce you to Process Control Instruments. Simple example of process control: Manual Control and Automatic Control. To give an unde

This article to introduce you to Process Control Instruments. To give an understanding of the terms used in instrumentation and to introduce you to basic process variables.

Instrumentation plays an important part in the efficient operation of any processing or production plant. Instruments enable the plant to operate smoothly and safely with a minimum of operating staff. Instruments help the operator to perform his duties. This course will give you a basic understanding of how the instruments function. A process is the changing of raw materials into a finished product. As raw materials flow through the process equipment they are subjected to various conditions. These conditions alter the raw material composition and chemical structure. It is important that these process conditions be accurately controlled at all times. The controlling is done by instruments. It is the operators that tell the instruments what to do. The operator who knows his instruments is the master. The instruments are his slaves or servants. When the instruments are properly used the process equipment operates correctly. When the process equipment operates correctly the finished products are up to specification.

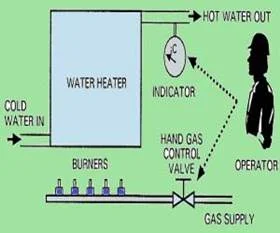

We will give a simple example of process control, as following:

Manual Control

The diagram above (see Figure) shows what is called MANUAL control. The process is temperature control. The indicator is a thermometer. The correcting unit is the gas control valve. The controller is the operator who uses his own judgement to keep the water temperature constant. Manual control has its uses as it is cheap to install and maintain, and simple to operate. However, it is very seldom used in industry because:

- The operator must remain in position at all times.

- It cannot be used if the operator is placed in a dangerous area.

- The process changes faster than the operator can react.

- A mistake by the operator can have dangerous results.

These problems are avoided by using automatic control.

Modern household appliances now use automatic control to make work easier. For example:

- Refrigerators and air conditioners use automatic temperature control.

- Washing machines use automatic heating and water control.

Automatic Control

The above diagram (see Figure) shows a simple automatic controller. The boiler now has the loop closed and no operator is required. The following items are added:

The above diagram (see Figure) shows a simple automatic controller. The boiler now has the loop closed and no operator is required. The following items are added:

- The temperature transmitter (T.T) which measures (senses) the temperature of the hot water and changes it to a standard signal.

- A signal line from the transmitter to the controller, the signal may be either pneumatic or electrical.

- A controller which keeps the temperature of the hot water at a position set by the operator (set point)

- The controller adjusts the correcting unit (automatic control valve) using an output signal line similar to the input line from the transmitter.

- The controller may provide alarm signals to alert the operator if the system fails. It may also shut off the gas if the water starts to boil.

- This is a very simple example of automatic control.

- Process Control Instruments can be very complex.

- If we take each part or device that is in a complex unit one by one the system is easy to understand.

Instrumentation uses a lot of words which need to be explained. Before we can talk about instrumentation and process control you need to understand the following words.

| Instrument | Any device for measuring, indicating, controlling, recording, and adjusting a physical or chemical property e.g. flow, pressure, acidity, weight, gas, concentration, etc |

| Instrumentation | A complete set of instruments used to control a process, e.g. refining, oil/gas production. LNG, LPG, etc |

| Indicator | A device which shows a measured value to the operator |

| Recorder | A device which continuously records measurements, either electronically or on an ink chart. It is used to show production figures, etc. |

| Process Loop | A group of instruments used to control a single process variable e.g. pressure, flow, level, etc. |

| Process | The operators word for a manufacturing unit e.g. refining, liquefying gas, etc. |

| Measured Variable or Process Variable (MV) | The value of the property being controlled by single process loop e.g. pressure, flow, level, etc. |

| Desired Value or Set Point (SP) | The value required by the operator |

| Error Signal (ER) | The difference between the measured variable and the set point should be zero for good control |

| Controller | A device, either pneumatic or electrical/ electronic, which adjusts the error signal to zero |

| Correcting Unit (Final Control Element) | A device which works on the command of the controller. It is used to adjust the measured value to obtain a zero error signal, e.g. control valve, etc. |

| Transmission | A method of standardizing signal sent from various parts of the plant |

| Transmitter | A device which takes a measurement and changes it into a standard signal |

| Transducer | A device which changes one form of energy to another; particularly from electrical to pneumatic |

The instruments in use are very varied, depending on how old the installation is. They may be air (pneumatic), liquid (hydraulic) or electric / electronic in operation. The way the information is shown or recorded may be simple, like a clock or thermometer. It may use the latest information technology to display information on a personal computer screen (video display unit).