Process control introduction, two processes sample being controlled: boiler temperature, hot water. computers in control systems, Off-line control, On

Process Control Introduction

There are many applications where part or all of a process has to be controlled. e.g. temperature, pressure, flow, etc. is to be maintained within some limit. For example consider a home heating system:

Here we have two processes sample being controlled-

Boiler temperature: a thermostat measures the boiler temperature and when it falls below a certain value switches on the boiler heater. When the temperature reaches a certain value it is switched off again (this is usually called on-off or two position control). Thus the boiler temperature stays around a particular value.

- The hot water is pumped through the radiators by a water pump which is controlled by a second thermostat. This thermostat is usually placed in the coldest room in the house. When the temperature in the room falls below a particular value the pump is switched on and hot water flows through the system. When the room temperature reaches the required value the pump is switched off. It can be seen that the major problem with, this system is that the temperature in only one room is being controlled the rest being heated up even if the temperature is satisfactory. It is possible to reduce the flow of hot water through each radiator by control valves fitted to each radiator but a more satisfactory method is to fit thermostatic radiator valves to all radiators except the one in the room where the pump thermostat is, i.e. two control systems in the same room are not needed. This allows the temperature required for each room to be set on the radiator thermostats which reduce the flow of hot water through the radiators when the required temperature is reached. This allows some rooms to be at a high temperature, e.g. dinning rooms, bathrooms, etc. and others to be at a lower temperature, e.g. bedrooms, unused box rooms, etc.

Thus even in a simple application like the temperature control in a house we can have a number of processes being controlled, e.g. boiler temperature, water flow rate, room temperatures. In a large process control system, e.g. a chemical plant many thousands of processes may be controlled.

The use of computers in control systems

Off-line control : the computer is not physically attached to the process. The operator reads data from instruments (temperature, pressure, etc.) which are then entered into the computer. The computer can then process the data and present results that can be used to modify the process. Such a control system is useful for long term examination of a process. On-line control : the operator reads the instruments and enters the data into the computer immediately using a terminal. Thus the results can be presented much faster than with off-line control. Again useful in applications where long term control is required, i.e. in stock control of a warehouse. Both of the above require the intervention of a human operator, thus:

- An error can occur with the operator taking readings incorrectly or typing wrong information

- The operator may not be fast enough in many applications, i.e. when many readings per second are to be taken.

on-ine control : computer connected directly to process using analogue to digital converters and digital input systems.

open-loop control : the operator interprets computer results and sets process parameters according to his decisions. So :

closed loop control: in this case the computer is in direct control of the process using digital output to switch on/off valves etc. and digital to analogue converters to read control parameters, e.g. pressure, flow rate, etc.

The human operator can, via an operators console, examine the current state of the process and from the keyboard modify the control loops to change the process.

The major advantage of using computers in control systems is that it is much easier to modify control parameters and implement complex control equations than with the previous analogue control systems.

These notes will mainly be concerned with closed loop on-line control systems.

Types of control

Sequence Control: a predetermined set of control actions need to take place so:

operation A - operation B - operation C

Each operation is controlled and when complete the next is started up. For example consider an automatic washing machine

1. open hot and cold water valves — mix until correct temperature and water volume is reached

2. switch off valves and start motor

3. after certain time stop motor and pump out water

4. enter new water for rinse and start motor

5. stop motor and pump out water — spin dry

each part of the process would be controlled depending upon the type of wash to be carried out, i.e. various water temperatures for different materials. Another application would be a steel rolling mill where a predetermined rolling sequence is used from a given ingot size and type.

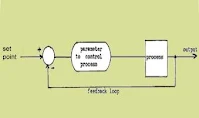

Regulatory Control: process parameters are maintained at a desired level (within specified limits or error) for a specified time. This involves taking a measurement of the output of the process feeding this back so it can effect the process and change the output. This is called ‘feedback. Consider:

Regulatory Control: process parameters are maintained at a desired level (within specified limits or error) for a specified time. This involves taking a measurement of the output of the process feeding this back so it can effect the process and change the output. This is called ‘feedback. Consider:

The set point’ is the required value of the output parameter, e.g. a temperature. This is compared with the output and the difference (the error) is fed into some control system that will effect the process in such a way to reduce this error to zero, e.g. switch on a heater to raise the temperature.

For example consider a simple on-off control system (thermostat) for a boiler temperature control. The operator sets the ‘set point

The boiler temperature is measured (Tm) and fed back and compared with the set point temperature Ts. The difference F = Ts — Tm controls a switch that enables and disables power to the boiler heater. If E>0, i.e. Ts>Tm the switch is closed and the boiler heats up. When T<=0, i.e. Ts<=Tm it is switched off.Control Actions used with feedback control.

There are four types of control action

1. on-off or two-position control

2. proportional control

3. integral control

4. derivative control

plus various combinations of these.

ON/OFF or two-position control

In many control applications it is satisfactory for the controller to operate at either of two levels rather than over a continuous range. In many applications the two levels are simple ON/OFF, e.g. valve open or closed. However, the two levels may not be ON/OFF, e.g two settings of a heater or forward/reverse of a motor. Consider a thermostat controlling a heater that controls the room temperature. The user sets the required room temperature (the set point). When the room temperature falls below this the heater is switched on and when it gets to the required temperature it is switched off. The operation may appear so

In many control applications it is satisfactory for the controller to operate at either of two levels rather than over a continuous range. In many applications the two levels are simple ON/OFF, e.g. valve open or closed. However, the two levels may not be ON/OFF, e.g two settings of a heater or forward/reverse of a motor. Consider a thermostat controlling a heater that controls the room temperature. The user sets the required room temperature (the set point). When the room temperature falls below this the heater is switched on and when it gets to the required temperature it is switched off. The operation may appear so

The major disadvantage with this type of control is that the controller output bears no relationship to the error signal, i.e. the output is ON/OFF or level 1 or level 2 no matter how high the error.

The control is either non or too much. In addition depending upon the sensitivity of the system the controller may well cycle at high frequency, e.g. the boiler being switched ON/OFF very rapidly as the temperature falls and rises. To prevent this many controllers have ‘backlash’ built in or have two limits provided. For example a room thermostat may be set to 700F and due to backlash it will switch on a 680F and off at 720F. This prevents the boiler being switched ON/OFF very rapidly if the deviation around the set point was small. In addition theoretical analysis of such a control system is difficult, i.e. the control action is discontinuous, and is often treated as two linear problems

(ii) with the system OFF

The ‘backlash’ built into control systems to prevent high frequency oscillations is usually called differential gap (discussed below).

Consider the following tank supplying water:

The aim is to maintain the level H in the header tank regardless of the flow out. This is done by switching the control valve on/off to allow water to flow into the header tank, i.e. when the level in the tank falls the valve is opened. when the level reaches the ‘set point’ it is closed.

If the response of the system was very fast the level could be kept at H plus or minus a small amount. However, the valve would be in continuous on/off operation and excess wear would result. Thus ‘backlash’ is built in which is usually called differential gap.

Differential Gap is the difference between the maximum and minimum value of the measured output variable when the system is running in a settled condition, i.e. when the flow out above is fixed. The operation would appear:

The effect of dead time in on/off control is to increase both the period and amplitude of the oscillation of the controlled variable.

For example in control of a water boiler the dead time could be caused by temperature differences in the water if the heating element and temperature sensing device were too far apart. This can be overcome by having a stirrer to mix the water.

Continuous control

The problem with on/off control is that the controller output bears no relationship to the magnitude of the error in the output, i.e. the control is non at all or too much. Although such control is fine for many simple applications a more continuous form of control is required in more complex situations. Consider the water tank level control on the previous page. When the level fell below the set point the valve was opened and stayed open until the level rose to the set point (allowing for differential gap). A more useful form of control would be to have a valve that could be open gradually to allow a varying flow of water. Thus when the level was well below the set point the valve would be well open and the flow very high and as the level reached the set point the flow would reduce to zero.

Proportional Control:

in this form of control the controller output xp is proportional to the error signal e. This can be expressed so:

xp = Ke

Where K is the constant of proportionality that is set according to the application. Thus the response of a system would appearIt is seen that so long as the error persists the controller gives a corrective signal, the magnitude of which is proportional to the error size. The proportionality constant K can be very important in the response time of the system. If K is high a particular value of error e would generate a higher correction signal than for small values of K. If K is too high oscillations could Occur so:

in this case the correction signal was so high the set point was overshot and had to be corrected again. It is possible for K to be so high that the system is unstable and will oscillate continuously. In the case of K being too small the correction signal would be too small to correct the error within the required time.

For each control loop K must be chosen to give the required system response to changes in output without causing oscillation. It may well be necessary to mathematically analyze the system to various inputs to determine K initially and then adjust it when the system is built.

For each control loop K must be chosen to give the required system response to changes in output without causing oscillation. It may well be necessary to mathematically analyze the system to various inputs to determine K initially and then adjust it when the system is built.

Integral Control:

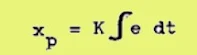

The problem with proportional control is that for a given error the corrective signal is constant and if this is insufficient to correct the problem the set point will never be reached In an integral control system to longer the error persists the more corrective signal is given, e.g. in a heating system if the temperature remains low the boiler output increases with time. In integral control the output of the controller is proportional to the time integral of the error signal e. This can be written:

in this case the correction signal was so high the set point was overshot and had to be corrected again. It is possible for K to be so high that the system is unstable and will oscillate continuously. In the case of K being too small the correction signal would be too small to correct the error within the required time. For each control loop K must be chosen to give the required system response to changes in output without causing oscillation. It may well be necessary to mathematically analyze the system to various inputs to determine K initially and then adjust it when the system is built.

Integral Control: The problem with proportional control is that for a given error the corrective signal is constant and if this is insufficient to correct the problem the set point will never be reached In an integral control system to longer the error persists the more corrective signal is given, e.g. in a heating system if the temperature remains low the boiler output increases with time. In integral control the output of the controller is proportional to the time integral of the error signal e.

This can be written: where K is the gain of the integral controller, i.e. the longer the error persists the higher becomes the corrective signal. This could appear:It is seen so long as the error signal is positive the correcting signal will occur at an increasing rate. The problem is that when e returns to $ a correction signal still exists so e must go negative to reduce it to Z. This results in the tendency of integral control to overshoot the set point and cause oscillations in the system output.

Derivative Control: In this case the faster the output deviates from the set point the higher the corrective signal. Consider an aircraft where the wings are to be kept horizontal. It the aircraft starts to tilt proportional control may not cope in that the aircraft may turn over before the tilt can be corrected. In this case the higher the rate of tilt the higher the corrective signal the pilot would apply to correct it. In this case the controller output xp is proportional to the rate of change of the error e. This can be expressed

xp = K de/dt

where K is the gain of the derivative controller. This could appearThus when the error is steady the controller output is 0 and only when e is changing will there be controller output. Hence an error can exist without corrective action being taken as therefore it is always used in conjunction with proportional or integral control or both. The advantage of this type of control is that the faster the output deviates from the set point the higher will be the corrective signal.

PID (Proportional Integral Derivative) Control (called three term control)

It is possible to combine two of the control types to from two term control but most general control systems use three term control expressed so:

where the K’s are the controller gains and e is the error signal. This is the general form of the PID equation used in control systems with the first term being the proportional control, the second the integral control and the third the derivative control. The values of K can be adjusted to change the effect of each control type on the output

Analogue Control Systems

Consider the following diagram showing analogue components for a control system :

This shows a process that may have many input parameters and many output parameters so there may be a large number of control loops of which one is shown. The components are:

- transducer: converts the process parameter (temperature, pressure, flow) into a voltage suitable to drive a voltmeter and electrical circuits

- display instrument: in many applications it is usual to have a visual display of parameters on a meter of some kind. This enables operators to examine the state of parts of the process

- set point dial: there is some means for the operator to set the desired value. This may be a dial marked in degrees or may even be attached to the display instrument. This enables the operators to see the set point and the actual output value at a glance. There may be additional dials to enable emergency action to be taken if the output departs too far from the set point.

- analogue controller: this has the electric (or mechanical) components to implement the control equation (PID or two state)

- amplifier to amplify the controller output so drive the :— -process interface: this may be heaters, valves, etc. to effect the process to reduce the error. In a typical system:

1. there may be many control loops as above

2. for each loop a set of hardware components similar to above must be provided

3. the analogue control elements tend to be limited in the mathematical operations that can be performed

4. the controller is hardwired’ making modification difficult. The K gain factors can be ‘tuned’ but the basic operation cannot be altered except by rewiring.

DDC (Direct Digital Control)

The idea behind DDC is to replace many of the components of the analogue control system with a digital computer running a real time operating system. Each control loop, possible many hundreds, would be serviced by the same digital computer: the maximum number of loops would be a function of computer processing speed, A to D conversion time, complexity of control equations, etc. Not all of the analogue components can be replaced by a digital equivalent and indeed some of the control loops may be more appropriate for total analogue control.

Components of the DDC system

The components of the analogue system that would not longer be required are:

- Analogue controller: instead of performing the computations with analogue 'hardwired’ circuits the digital computer would be programmed to simulate the required control action. In addition the digital computer could be programmed to perform far more complex control actions than the typical PID equation and the control action would be easy to modify. Many analogue controllers could be replaced by a single digital computer.

- display instruments: all information could be displayed on a display screen.

- set-point dial: the set-point could be defined in the program and modified from the operators console or terminal.

- comparitor: the comparison between the set-point and the actual value would be done by the digital computer.

The components that could not be replaced are:

- transducers and associated equipment

- process interface devices

In addition some new equipment is required in the DDC system:

- Multiplexors to scan the transducers, i.e. an electrical switch that can be set under program control to sample at a particular time

- analogue to digital converters to convert the analogue signal from the transducers to a digital representation for processing

- digital to analogue converters to convert the digital signals from the computer to analogue form to drive the process interface equipment. Certain signals to the process could be in digital form, e.g. open/close a valve, others would be in a continuous analogue form, e.g. a valve to control variable flow.

A typical DDC system may appear:

This diagrams shows a number of transducers being scanned by the multiplexer, the signals converted into digital representation and processed by the DDC computer. The computer outputs are either a simple binary on/off signal that can go directly to the process control interfaces or a value that has to be converted into analogue form first. The operators can examine each loop from the console, e.g. error values, modify set-point, etc., or get a global view of the whole of the process, e.g. the interaction of various loops.

Control Actions in DDC

In analogue control systems the control action are performed on continuous analogue signals. With DDC these operations must be approximated by finite difference calculations. For example the PID (Proportional Integral Derivative) equation would be:

where :xpn = value of process control signal for time period n

en = value of error signal at time period n

[]t= sampling interval tn - tn-1

and K1, K2 and K3 are constants (can be modified under operator control).

In this case samples are taken over []t and the new controller output calculated. As the sampling interval becomes smaller this equation more closely. approximates to the ideal PID equation seen in previous sections.

Consider an application where 100 control loops are to be serviced and the computations for each loop take 100 microseconds. Such a computer would therefore sample each input every 100 * 0.0001 = 0.01 seconds. In practice some time would be lost in the multiplexer, A to D, etc. so the time would be longer. In many process control applications, e.g. chemical plant, such a sampling interval would be sufficient. However, if any of the control loops needed to be sampled faster than this a faster processor would be required or such inputs handled by a separate computer. In a large plant there could well be many computers looking after control loops in sections of the plant and reporting to a Supervisory computer (see next Section) that looks after the whole of the plant.Advantages and Disadvantages of DDC

The advantages would be:

- More sophisticated control: it is easier to program a complex control strategy with DDC than analogue ‘hardwired’ elements. In addition extra facilities such as safety checks, trend analyses, etc. could be programmed into the system.

- Control flexibility: it is much easier to modify the control strategy that is programmed with DDC than to alter the ‘hardwired’ analogue circuits.

- Equipment cost: seeing as the DDC computer can look after many control loops it would save the cost of analogue controllers and associated equipment. In fact there would be some break-even point in the number of control loops to justify DDC. With microprocessors this is getting less and less.

- Reliability: digital equipment tends to be more reliable than analogue. It is also easier to build in ‘backup’ systems.

Disadvantages are:

- Requirements for a backup system: seeing as the computer looks after many control loops a system failure could be catastrophic. Hence many DDC systems have built in backup (second and even a third processor).

- Programming costs: the programming cost for a complex DDC system could be a very high proportion of the total system cost (50% or even higher). In fact such costs are often underestimated.

In the analogue control of a complex plant one of the major problems was to get an overall feel ofr the plant operation. Although each loop could be examined on an instrument, of which there may be many hundreds, it was difficult to ‘step back’ to get a global view. In a DDC system the operators console could look at the plant from many levels. Initially it could display the overall plant operation. The next level down would be to examine subsections of the plant then a particular process then the individual loops within the process. A loop could be modified and its effect on process and then plant be assessed.

Supervisory Computer Control

It was soon realized that the computer could do far more than simply replace analogue control systems with DDC systems. The computer could 'remember' far more data for trend analysis and from this modify the performance of the process. Control of the overall process is by control of the individual feedback loops by changing the set-point values.

It was soon realized that the computer could do far more than simply replace analogue control systems with DDC systems. The computer could 'remember' far more data for trend analysis and from this modify the performance of the process. Control of the overall process is by control of the individual feedback loops by changing the set-point values.

Supervisory computer control' denotes a computer process control application in which the computer determines the appropriate set-point values for each control loop in order to optimize some performance objective of the entire process. The object may be maximum production rate, minimum unit cost, or some other objective that pertains to the process. The computer has a mathematics model of the process that is used to calculate the set-pont values to optimize the objective. In addition it could look after any 'sequence control' required by the process. A typical system may have a number of DDC systems being controlled by a Supervisory computer so:

The supervisory computer can take much of the load off operators giving summary reports on operators consoles. In addition an emergency action to be taken in case of plant failure could be built into the system.

Computers in Process Control: Summary

DDC has been used for may years in the process control of large complex systems. Computers and programming were expensive so the ‘break even’ point to replace analogue systems with DX was high. However, with microprocessors the hardware is now very cheap and by sharing the software cost over a large number of systems this unit cost could be low. Thus even in domestic control systems, e.g. central heating, washing machines, etc. where the norm was analogue control, digital control systems are now available. Such digital control systems should be cheaper, able to carry out a wider range of more complex tasks and be far more fault free than the analogue equivalents.

- [accordion]

- 1. Practical Process Control

-

- 2. AspenTech Hysys Advance Process Modeling

- 3. Chemical Engineering Process Simulation

- 4. Design and Control Distillation Systems for Separating Azeotropes

- 5. FEED Oil Gas Project Critical Factor

- 6. Handbook Control Valve

- 7. Handbook ISA Control Valve

- 8. Modeling & Simulation of Catalytic Reactors

- 9. Petroleum Refinery Process Modeling

- 10. Process Control Modeling, Design, Simulation 2023

- 11. Process Dynamics and Control Wiley (2017)

- 12. Schlumberger PIPESIM Training

- 13. Sensor Selection Guide Optimizing Process

- 13. Understanding Process Dynamics and Control Cambridge

- 1. Practical Process Control

- 2. AspenTech Hysys Advance Process Modeling

- 3. Chemical Engineering Process Simulation

- 4. Design and Control Distillation Systems for Separating Azeotropes

- 5. FEED Oil Gas Project Critical Factor

- 6. Handbook Control Valve

- 7. Handbook ISA Control Valve

- 8. Modeling & Simulation of Catalytic Reactors

- 9. Petroleum Refinery Process Modeling

- 10. Process Control Modeling, Design, Simulation 2023

- 11. Process Dynamics and Control Wiley (2017)

- 12. Schlumberger PIPESIM Training

- 13. Sensor Selection Guide Optimizing Process

- 13. Understanding Process Dynamics and Control Cambridge