Differential pressure gauges function are suitable for measuring the following quantities: filter contamination, clogging of bags, Over-pressure, Flow

Differential Pressure, the higher the liquid level in the tank, the more pressure there will be on the bottom of the tank. This pressure is known as the hydrostatic pressure. Hydrostatic pressure is used, for example, in a water tower to ensure sufficient pressure in the supply lines to the consumers.

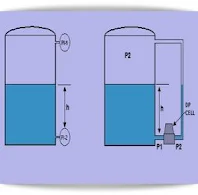

By mounting a manometer on the bottom of the tank, the physical property of pressure can be used to measure the height of the liquid, see figure.

Differential pressure gauges function are suitable for measuring the following quantities:

- Monitoring of filter contamination

- Monitoring of clogging of bags in bag dust collector

- Over-pressure measurement in the clean rooms

- Flow measurement of gaseous and liquid media

- The pressure shown on the manometer, can be calculated using the formula:

p = h x d x g

Where:

p = pressure in Pa.

h = height of the liquid above the measuring point in meters.

d = specific mass in kg/m^3.

g = gravitational constant 9.81/s^2

If a certain tank always contains the same liquid then density can be considered a constant. It is then possible to design the scale so that the height of liquid, in centimeters or meters, can be directly read.

In a closed tank where pressure is above the liquid, this method cannot be used because the pressure shown on the pressure gauge would be the sum of pressure on the liquid plus the hydrostatic pressure of the liquid. In this case the hydrostatic pressure could be determined by measuring the pressure above the liquid and subtracting it from the total pressure measured: P2 - P1.

This is a bit complicated and less accurate because two gauges are used, both having a certain inaccuracy. It is better to use a differential pressure (DP) gauge. This can give hydrostatic pressure, or the level, directly. A diaphragm is usually used as the measuring element.

A commonly used instrument that works on this principle is the D/P cell (Differential Pressure Cell), which functions as a differential pressure transmitter as shown in figure.

On the high pressure side, the pressure is:

P1 = (h.d.g) + P2

On the low pressure side, the pressure is: (P2)

The differential pressure is:

P1 - P2 = (h. d. g) + P2 - P2 = h. d. g

Which equals the hydrostatic pressure. Thus:

P = P1 - P2 = h. d. g

If there is a gas above the liquid that may condense in the measurement line (for example steam). The line is completely filled with the liquid, see figure. In this way, it is ensured that the pressure on that side (P2) is constant.

Area Of Application

- Monitoring filter health

- Flow Rate Measurement

- Detecting Scale Buildup

- Detecting Leaks

- [accordion]

- 1. Differential pressure flowmeter working

-

- 2. Instrumentation and Control

-

- 3. Advanced Detector Instrumentation in Nuclear Particle

- 4. API RP 554 Part1-3rd_Ed May 2021 Process Control Systems Functions

- 5. Gas Measurement Technology Theory_and Practice Measuring Instruments

- 6. Measurement and Control Basics, Fifth Edition

- 7. Photonic Instrumentation Sensing and Measuring with Lasers 2023

- 8. Piping and Instrumentation Diagram Approach 2023

- 10. Reliability data for safety instrumented systems PDS data handbook

- 1. Differential pressure flowmeter working

- 2. Instrumentation and Control

- 3. Advanced Detector Instrumentation in Nuclear Particle

- 4. API RP 554 Part1-3rd_Ed May 2021 Process Control Systems Functions

- 5. Gas Measurement Technology Theory_and Practice Measuring Instruments

- 6. Measurement and Control Basics, Fifth Edition

- 7. Photonic Instrumentation Sensing and Measuring with Lasers 2023

- 8. Piping and Instrumentation Diagram Approach 2023

- 10. Reliability data for safety instrumented systems PDS data handbook